The Bugatti 'Macaron' badge — A unique component made of silver

(October 17, 2020) MOLSHEIM, France — 150 grams of sterling silver. Finest embossing quality, high-gloss enamel and a 3D effect. Ever since the year the brand was founded, the Bugatti badge, the Macaron, has symbolized exclusivity, luxury, design and outstanding hand craftsmanship on the horseshoe radiator.

“The importance that the Bugatti Macaron still has for our brand today is shown by its unrivaled quality, the loving attention to detail, and also the weight,” says Stephan Winkelmann, president of Bugatti.

“It is one of the very few components on our vehicles where weight does not play a role. The solid badge made of 970 sterling silver has a very high-quality design due to its size, and this is more important to us than a lightweight component. The deep-red and unmistakable oval on the vehicle has transported the famous name BUGATTI out into the world ever since the company began, and embodies the symbolic power of our brand myth.”

In the year when the company based in Molsheim, France was founded, towards the end of 1909, company founder Ettore Bugatti attached an oval badge made of enamelled metal onto the radiator grille of the Bugatti Type 13, the first official Bugatti. The idea for the oval shape with white lettering on a red background originated from Ettore Bugatti himself. He had already developed a similar logo for his previous employer Deutz in Cologne.

When he started his own vehicle production, Bugatti intentionally chose a flat, but high-quality brand badge. According to the design instructions, the shape formed by cutting a cylinder with a diameter of 45 mm at an angle of 30 degrees. The popular and almost inflationary use of radiator figures at the time would have only spoiled the design of his vehicles. The only exception remains the dancing elephant on the Bugatti Type 41 Royale from 1926 — this is a replica of and tribute to a sculpture created by his deceased brother Rembrandt.

In addition to the easily legible name lettering in white on a red background, the badge also features the initials EB (for Ettore Bugatti) above this in black, as well as 60 red dots on a white surrounding border. Red stands for power and passion, white for elegance and nobility, and black for excellence and courage. According to the legend, the 60 dots symbolize pearls or threads in a style that conformed to the “Art Nouveau” fashion. In those days, they were used like splints to produce a permanent connection on mechanical parts – and the reliability and durability of his vehicles was something that was always very close to Ettore Bugatti’s heart during his lifetime. Bugatti changed the appearance of the Macaron only slightly over the course of the years.

For more than 15 years now, the emblems of the modern Bugatti era have been handcrafted at the „Poellath GmbH & Co. KG Münz- und Prägewerk“ in Schrobenhausen, Bavaria. The company produces the tools for this itself, and the manufacturing process is done by hand. “Such a fine component can be made only by hand in this high quality,” says Thomas Demel, CEO of Poellath.

For more than 15 years now, the emblems of the modern Bugatti era have been handcrafted at the „Poellath GmbH & Co. KG Münz- und Prägewerk“ in Schrobenhausen, Bavaria. The company produces the tools for this itself, and the manufacturing process is done by hand. “Such a fine component can be made only by hand in this high quality,” says Thomas Demel, CEO of Poellath.

Even the smallest steps are performed precisely by hand. Poellath is the only company worldwide that is capable of producing this badge with the 3D effect from enamel. A hidden champion that specializes in the production of high-quality metal emblems.

The company Poellath was founded in Schrobenhausen in 1778 and has been family-owned ever since. As early as 1825, the King of Bavaria recognized the craft company for its embossing technique; this was followed by a further award at the world exhibition in Brussels in  1873. In 1884, the company moved from the old part of Schrobenhausen to its current location. In 1895, electrical engineering replaced steam power in production, and the company added its own electroplating workshop. In addition to making badges for Bugatti, the company’s core competency, namely embossing metal, also includes embossing commemorative coins, badges, awards and medals for clubs and companies.

1873. In 1884, the company moved from the old part of Schrobenhausen to its current location. In 1895, electrical engineering replaced steam power in production, and the company added its own electroplating workshop. In addition to making badges for Bugatti, the company’s core competency, namely embossing metal, also includes embossing commemorative coins, badges, awards and medals for clubs and companies.

The company has been producing the emblems for Bugatti since 2003, initially for the Veyron 16.4.

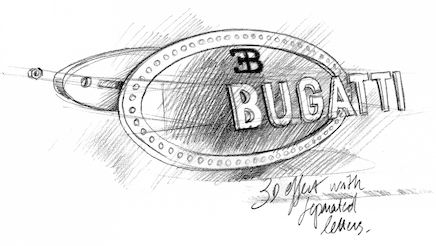

Development of the Macaron for the Chiron started in 2014. “The new badge was to be larger than before, and also have a new and previously unknown visual depth. The Bugatti lettering and the dots at the edge are therefore located on one plane and are enamelled, as is the background which is almost two millimeters lower. This creates a genuine 3D look and feel,” explains Thomas Demel. The badges for the Chiron increased in width by 14 millimeters and in height by 8 millimeters compared with the Veyron. The exact embossing is sharp and precise even when examined closely.

Today, most badges are delivered in red. Only very few vehicles, such as the Chiron Noire or Super Sport 300+ receive a Macaron in black. In addition to the Macaron on the radiator grille, Poellath also produces smaller badges. These are used for the vehicle key, for example.

Including the enamel and the fastening screws, the emblem weighs an impressive 159 grams. Around 20 skilled workers from different departments at Poellath work on the exclusive component for a total of around ten hours spread over several days. The 970 silver base metal is embossed several times with up to 1,000 tonnes as part of a multi-stage process. The Bugatti lettering is raised from the base by 2.1 mm at the level of the border. In contrast to casting methods, the contours achieved by embossing are much sharper and of much higher quality – provided that the right tools are used. After embossing, the emblem passes through the enamelling process.

Enamel is glass that has been fused onto iron, a manufacturing process that goes back over a hundred years. One of the very special challenges when developing the Macaron was the specification that the enamel used had to be free of toxic materials. Half of the enamel typically used before consisted of lead. The enamel now used is made of inorganic compounds such as silicates and oxides, which makes processing significantly more demanding and fuses with the silver when melted. The vitreous grains of the granulate melt at extreme heat between 750 to 900 degrees Celsius and are permanently fused with the silver base material in a bond that is difficult to dissolve.

Enamel is glass that has been fused onto iron, a manufacturing process that goes back over a hundred years. One of the very special challenges when developing the Macaron was the specification that the enamel used had to be free of toxic materials. Half of the enamel typically used before consisted of lead. The enamel now used is made of inorganic compounds such as silicates and oxides, which makes processing significantly more demanding and fuses with the silver when melted. The vitreous grains of the granulate melt at extreme heat between 750 to 900 degrees Celsius and are permanently fused with the silver base material in a bond that is difficult to dissolve.

A special feature is the fact that the typical convex curvature of the emblem occurs on its own. This is because enamel already solidifies at 600 degrees, while the silver underneath continues to contract. The approximate 0.5-millimeter thick enamel layer in the background therefore solidifies much earlier than the metal, and this automatically produces a slight convex curvature of the entire Macaron. This in turn supports the 3D effect.

Only the raised glass-like compound can then be sanded, finely sanded and polished by hand, while being repeatedly checked during this process. “No machine is capable of doing this due to the different curvatures and the surfaces located at the back. The individual dots are also enamelled and processed by hand,” says Thomas Demel. Finally, the fastening studs made specially out of one piece are brazed on and the surface is checked once more. Incidentally, the fine, unavoidable pores in the enamel are not a defect, but show the uniqueness of the manufacturing process and make each individual badge a unique one-off.

“Enamel ensures the highest-quality colors on metal. It remains color-fast and brilliant for decades, if not centuries. It also shows the special character of hand craftsmanship and the richness of detail. If the base material is made of sterling silver, like with Bugatti, its quality is increased even further. That is unique in this form in the automotive field,” explains Thomas Demel.