The history of Chrysler Assembly plants — The early years

1924 Chrysler — The first Chrysler

By Peter Hubbard

Abandoned Cars and Trucks.com

Part 1 of 3

(July 20, 2017) Did anyone happen to hear some loud moans or groans — maybe even a howl or two emanating from the cemetery up in Sleepy Hollow, N.Y., on Halloween night? If so, I wouldn’t be the least bit surprised. No, I’m not referring to possible Halloween pranksters dressed up like The Headless Horseman — or perhaps some ghouls warming up their vocal chords.

These sounds might have been heard near the grave of a prominent ex-resident of Sleep Hollow — namely, one Walter P. Chrysler, founder of the Chrysler Corporation.

If you’ve been keeping track you know it was partially adopted by Italy’s Fiat Automobiles in 2009 as part of the company’s bankruptcy reorganization. Then the remaining 41 percent owned by other entities, including the United Auto Workers Union was purchased in January 2014, completing the transformation over to FCA — shorthand for Fiat Chrysler Automobiles.

There are two possible reasons for Chrysler rolling over in his grave and creating a ruckus. First is the fact that the Walter P. Chrysler Museum located at company headquarters in Auburn Hills, Mich., was permanently shuttered in December to make way for other company operations – possibly Maserati offices.

Second is the fact that FCA recently announced that in the process of re-shuffling its production of cars, trucks and Jeeps to ensure greater profitability, no Chrysler cars would be produced at plants located in the United States by the end of 2017.

It seems both of the two entry level cars in the company’s product line — the Dodge Dart and Chrysler 200 — will not only cease being produced at the first’s Sterling Heights, Mich., assembly plant at the end of 2016, both models will vanish from FCA showrooms entirely if the firm does not find a new “manufacturing partner.”

It seems both of the two entry level cars in the company’s product line — the Dodge Dart and Chrysler 200 — will not only cease being produced at the first’s Sterling Heights, Mich., assembly plant at the end of 2016, both models will vanish from FCA showrooms entirely if the firm does not find a new “manufacturing partner.”

That plant will be revamped and equipped to handle Ram 1500 pickups. The other current car models — the Chrysler 300, Dodge Charger and Challenger are assembled at one of the company’s Canadian plant, located in Brampton, Ontario. The smaller vehicles in the line-up, the Dodge Journey and Fiat 500 are being built in the Toluca Assembly Plant in Toluca, Mexico.

This truly marks the end of an era for Chrysler branded cars, which have been rolling off of American assembly lines for over 90 years now since 1925, in fact. During that time Chrysler cars — along with the company’s various brands, which have included Dodge, Plymouth, DeSoto, Imperial, Jeep, Eagle and Ram have been assembled at 24 different plants in North America — 19 in the United States, three in Canada and two in Mexico

For those automotive history buffs, or manufacturing and assembly nerds willing to roll down memory lane with me awhile, I’d like to share a few details about Walter P. Chrysler, the man who started the company, and then provide more details about the 24 assembly plants to fly the Chrysler banner over the years — as Chrysler Corporation, DaimlerChrysler, or FCA. And where pertinent, we’ll provide details about the key models produced at each plant while in operation.

So for those not especially interested in automotive history … you’re excused to move on to another story. But if you’re an automotive history buff in particular, with a particular interest in Chrysler, we trust it proves educational — perhaps even enlightening.

But to make the information a bit more digestible, this will be divided into a three-part history lesson, with a new “episode” posted over the next three weeks, since presenting a single 5,000-word web story would tax the interest of even the most avid history nerd.

Walter Chrysler with his first car

Walter P. Chrysler Story

Walter Percy Chrysler was born on April 2, 1875, in Ellis, Kan., where his father Hank Chrysler was an engineer for Union Pacific Railroad. Blessed with many of the same mechanical skills as his father, Walter P. gravitated toward the railroad industry in his early career, starting out as an apprentice machinist in the same Union Pacific shop where his father worked in 1893. But talent and ambition resulted in him moving up the ladder, and landing various engineering and management jobs with other railroad company around the country over the next 15 -18 years .

The pinnacle of his railroading career took him to Pittsburgh, where he became the works manager at the Allegheny locomotive erecting shops for the American Locomotive Company (ALCO) with a handsome salary (for that day) of $12,000 a year.

Chrysler's career shifted gears from trains to automobiles in 1911 when he received an invitation to meet with James J. Storrow, a Boston banker on the board of directors of ALCO, who was also one of the bankers that had taken over General Motors from founder William C. Durant. He was also serving as president of GM at the time, and arranged for Chrysler to meet with Charles W. Nash, president of Buick Motor Company, who was looking for a skilled production chief.

Chrysler's career shifted gears from trains to automobiles in 1911 when he received an invitation to meet with James J. Storrow, a Boston banker on the board of directors of ALCO, who was also one of the bankers that had taken over General Motors from founder William C. Durant. He was also serving as president of GM at the time, and arranged for Chrysler to meet with Charles W. Nash, president of Buick Motor Company, who was looking for a skilled production chief.

He was quickly designated Buick new Works Manager, (in charge of plant production) at Buick’s Flint, Mich., headquarters.

Despite suffering a 50 percent pay cut (to just $6,000 annually), Chrysler jumped at the chance to prove himself in the emerging auto industry.

The following year Nash was named president of GM, but also kept the same title at Buick blocking Chrysler’s rise in the company. A talented engineer, Chrysler found many ways to reduce costs. That talent would prove useful for the duration of his career. Among his many cost-cutting strategies was putting an end to finishing automobile undercarriages with the same quality of finish that the body received.

Realizing his efforts were saving Buick tons of money, one day in 1915 he decided he deserved a raise. So he marched in Nash’s office, demanding a $25,000 salary — and got it. The following year Durant regained control of GM with the help of chemical industrialist Pierre du Pont. Eager to keep top talent, Durant offered Chrysler the then-unheard-of salary offer of $10,000 a month for three years (165,000 in today’s dollars), with a $500,000 bonus at the end of each year, or an equal amount of GM stock.

While the salary was incredible, he was unable to get along with Durant. So Chrysler decided to leave GM after his contract expired. He was quickly recruited by various investment banks to, help bail out ailing automakers, including Willys-Overland and Maxwell-Chalmers. His cost-cutting skills were outstanding, but came too late save Willys.

However, he was able to stabilize Maxwell-Chalmers, and, used the millions earned from selling his GM stock to begin engineering his own types of vehicles and re-brand Maxwell into the Chrysler Corporation.

On June 6, 1924, Maxwell-Chalmers became the Chrysler Corporation, and the remaining Maxwell models were sold and the name discontinued. The very first pre-production “Chrysler” — a phaeton touring car — began rolling off the old Maxwell assembly line in Highland Park, Mich., in late 1924 as a 1925 model. Highland Park was not only the site of the first Chrysler assembly line, it soon expanded and became the firm’s corporate headquarters. Chrysler brass would retain officers there until the corporate relocation to new headquarters and technology facilities in Auburn Hills, Mich.

Within five years Chrysler would expand operations with the acquisition of the Dodge Brothers car company, and the addition of the Plymouth, DeSoto and Imperial nameplates, giving him a range of makes and models that would enable him to challenge GM, his former employer.

To make the cataloging of the various assembly plants easier to digest, they are being listed here in chronological order, with key information about the products assembled, and whether or not each is still in operation.

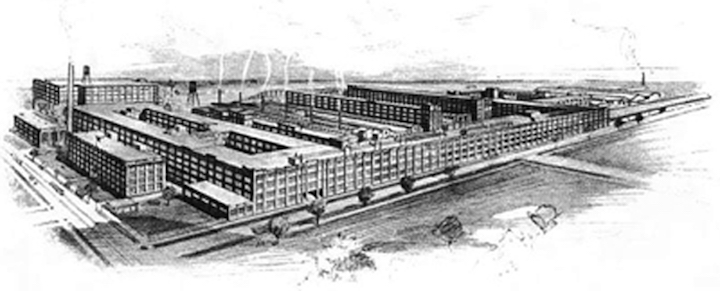

Highland Park engine plant

1920’s: Chrysler Launch and Expansion

Plant No. 1) Elements of Chrysler’s very first assembly plant located in Highland Park were built as early as 1910, when several early automakers, including the Grabowsky Motor Company, Brush Runabout Company, and Gray Motor Company established operations on the site. Those facilities were acquired by Maxwell in 1918, before Chrysler models first began rolling off the assembly line in 1925. Status: Out of operation.

Plant No. 2) Chrysler’s second plant was Maxwell’s original assembly line – the Jefferson Avenue Assembly plant, opened by Maxwell Motors in 1907. It was one of the primary assembly plants for Chrysler brands until it was closed in 1990 to make way for a brand new assembly facility — Jefferson Avenue North, opened in 1991 near Grosse Point Park.

It has been expanded twice to roughly 3 million square feet, and produces the Jeep Grand Cherokee. It uses the original site of the Hudson Motor Company location that was originally built during the 1940s as a storage lot for newly manufactured vehicles.

Cars were assembled at the site by first Hudson/Nash – then American Motors for some 47 years. Status: Active.

A plant was re-built on the site in 1993 to assemble the Jeep Grand Cherokee, but it will switch to the revived Jeep Grand Wagoneer model when it debuts in 2018.

1926 Dodge Brothers sedan

Plant No. 3) Chrysler’s third plant was located in Windsor, Ontario, Canada. The complex itself dates back to 1916, when Chalmers set up a branch factory. Maxwell opened a factory nearby shortly afterwards. When Chrysler bought Maxwell and some of the bankrupt Chalmers assets, the Windsor location was consolidated.

After the purchase of Dodge Brothers, located in Toronto, all Chrysler company activities were moved to Windsor and become Chrysler Corporation of Canada Limited. After acquiring the Chalmers site, Chrysler built a new factory on Tecumseh Road which assembled only Chrysler brands —20,010 cars in its first year, which gave Chrysler a larger market share in Canada than in the United States.

Since the early 1980’s it has handled mainly minivan production, and currently assembles the Chrysler Pacifica — the last minivan in the company’s product line. Status: Active, assembling Pacific minivans.

Dodge main plant in Hamtramck

Plant No 4.) The fourth and final assembly location for Chrysler brand vehicles during the 1920’s was the former Dodge Main Plant, located in Hamtramck, Mich. Originally built in 1910, it remained in operation until age caught up with it in 1980. In addition to the assembly line, the Dodge Bros. purchase brought with it new foundries capable of producing engine blocks and cylinder heads, which meant Chrysler no longer depended on outside vendors to supply these items. Status: Out of Service

Plant No. 5) Lynch Road Assembly Plant, Detroit — Lynch Road was opened to assemble new DeSotos and Plymouths in 1928 at 6334 Lynch Rd. Production ended in April of 1981, and production capacity was moved to the Newark Assembly plant in Newark Delaware. Status: Out of service

Plant No. 6) Plant number six was a former Graham-Paige facility, located in Stockton, Calif. It was acquired in 1926 and was used until 1954 to assemble the Dodge B Series trucks and vans, as well as Plymouth trucks and panel delivery trucks in the ‘20s, ‘30s and ‘40s. Status: Out of service

Next, we’ll review the history of Chrysler’s North American assembly plants No. 7 though No. 18, and cover the company history from the Great Depression of the 1930s, though the Chrysler bankruptcy of the 1970’s.